A recent question on twitter gave me the opportunity to spell out the technique I use to teach 3D printing to kids. This is also similar to the technique I use to teach it to adults.

I could write a book on this subject. In fact, now that I write that down, I think I’ve got a new project. But I can also summarize the process in a couple of tweets.

I’ve had the opportunity to refine the process many times. So this is less the right way and more the way I would teach it if asked to teach it tomorrow.

The basic goal is to get someone excited about doing it themselves. There are a couple of different approaches. The best way is to get them doing it themselves as soon as possible. That means you need computers and a couple of 3D printers. The ideal situation is one computer per 2 students, and one 3D printer per 4 students minimum. However, that’s not always possible. Maybe you’re in a situation where it’s just you presenting in a traditional sort of lecture environment. Either way, the basic steps are the same.

Step 1 – Create Something

I like to start by telling people that 3D printing is a 3D step process. (1) Creating or getting the 3D model, (2) preparing the 3D model, and (3) running the darn machine. Each step has it’s own tools and you need to become acquainted with all of them to be a 3D printer.

In the past I started with steps two and three, preparing and running the printer, because that’s where the “3D printing” happens, but lately I’ve decided that starting at the very beginning is the very best place to start.

Whether you’re doing the creation in front of them, or you’re getting them oriented on

Tinkercad, it’s important to start with a very basic project. A name tag or broach demonstrates navigating the 3D view, creating basic shapes, resizing, combining them together, putting objects on top of other objects and boolean operations. If you’re doing the modeling, you can do this sort of project in front of a group in 10 minutes. If they’re doing it, expect this part to take an hour.

I like Tinkercad for this because it is the simplest 3D modeling software I know, it has the same 3D view navigation controls as Cura, and it’s easy for adults and children, and it’s free. They can set up an account right there or they can use an account you’ve set up ahead of time for the class.

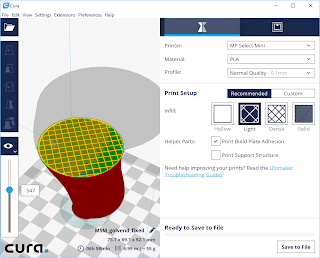

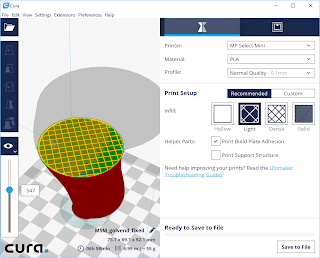

Preparing the 3D model

Once you’re done making something or having them make something, the next step is preparing the model. Teach them briefly about what a slicer is, how it fits into the 3D printing process. Mention how 3D models are just shapes, and a 3D printer can’t print a shape. It needs to figure out how to create that shape in layers, and how to draw each layer. Show them the layer view or 3D print preview, Show them the lines and layer of the process. Mention shells and infill. Tell them that the output of the slicer is a set of instructions called GCode that the 3D printer is going to follow, pretty much blindly, so it’s important the slicer gets it right. Then tell them how to move the gcode to the printer before starting the print.

I like to use Cura for this one. Again, it’s the most user friendly of the slicers and it puts on a good show. However, I have to mention that other slicers require you to push a button before it gets to the actual slicing, so, you know, be prepared if you ever run into a setup using Ideamaker or Simplify3D.

Attempt to insure the print is only going to take about 15 minutes, and take the opportunity to demonstrate the model manipulation tools, especially the scale operator. It’s a good time to talk about how a little change in scale can result in big changes in the print time and material used.

So after showing them the previous and showing them to check the first layer (seriously people, I can not tell you how many failed prints can be caught just by scrubbing the layer to the bottom and checking), it’s time to move the gCode to the printer, whether that’s sneakernet or if you have a fancy printer you can use wifi with. Though, generally when you’re out and about, wifi is often a problem, so expect to be shuffling SD cards.

Running the Machine

Then you find the print, press start, and make a big show of the absolutely nothing that follows. Point out that this is perfectly normal, that the print is just heating up, and when it’s done it will start moving.

Then, while you’re waiting for the print, now you lecture. You’ve got their attention and their not going anywhere while this is happening, so it’s time for the meat. You’ve got 15 minutes to cover safety first, and then to temper expectations.

Safety First

Normally I would want to put this discussion at the very first, and I mention that to the group. But while the print is happening is the perfect opportunity to take a pause and talk about something important. So before we talk about or do anything else, it’s time to talk safety.

I like to point out that 3D printing is pretty safe. For as many hack 3D printers that are out there, the number of incidences are pretty low. That said, there have been a handful of property damaging fires and one fatality where a 3D printer was involved, so it’s important to have a healthy respect for the machine.

In a large group I might ask the crowd what they thing the danger points are. Guide them to the fact that

- 3D printers are machines designed to generate heat

- 3D printers move on their own accord and don’t care what’s in the way

- 3D printers are electrical machines, and electronics, especially cheap electronics, generate sparks

- And 3D printers, generally, lack enough sensors on them to tell when something’s going wrong

Fortunately, it’s easy to mitigate these risks with a few simple rules. They are:

Safety Rules:

- Keep flammables away from the 3D printer. The hot end can get really hot.

- No dangling clothing or jewelry around a moving printer. it doesn’t care if you get in the way.

- Watch your prints as much as you can, especially at first, and know where the fire extinguisher is.

And if you’re going to own a 3D printer yourself, you also need to keep in mind the following:

- Keep your 3D printer in a well ventilated area.

- Own a fire extinguisher, keep it near.

- Have fire detection near where your 3D printer is.

Hard Truths

Then, it’s time to hit them with the

cold, hard truths about 3D printing. This discussion is mostly fluff while you’re waiting for the print to finish. Depending on how fast you talk or how many questions they’re asking, you may or may not get to every point on this list, and it doesn’t matter. These are things they will learn given time.

- Be prepared to learn

- This isn’t a magic push-button-get-christmas machine

- 3D printing is a lot slower than you expect, but when it’s done you have a thing and it’s not going away

- It takes time and effort to make anything

- There are tons of models for 3D printing out there, and yet the thing you want to print probably hasn’t already been modeled

- Sometimes your machine breaks and needs to be fixed

Now, hopefully you’re kinda playing this like they’re all bad things. You’re getting down on 3D printing at this point. You’re audience is hopefully starting to feel heavy, like maybe they’ve made a mistake. And at some point your print will finish, and you can stop whatever you were saying and go “But never mind that, because I just made this from nothing, and it’s super cool” and hold it up to thunderous applause.

What are you going to make?

Then leave you audience with a challenge. “So now that you know what’s possible, what are you going to make?” Take a bow.

And if this all seems a little theatrical to you, congratulation, you’ve just learned the trick to good teaching. Be lively, be animated, be excited, be entertaining. It doesn’t matter the age, everyone loves a show. And they will be learning while they do.

Well, there you go, everything you need to know to teach 3D printing to others. Now if you’ll excuse me, I have a book to outline.